Home » Building Component Visualizer

Metal Building Component Visualizer

Every component in an Ironbuilt steel building is manufactured using only the best commercial grade U.S. steel. At every stage of production careful attention is paid to ensure the quality and integrity of our steel buildings.

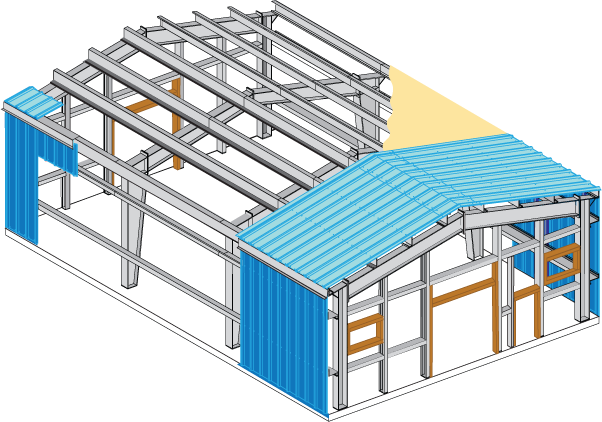

Similar to a human body, the primary mainframes and secondary framing serve as the skeleton, while the sheeting functions as the skin. The Building Component Visualizer below is an interactive virtual tour of the components in an Ironbuilt metal buildings. Simply scroll over the area of interest indicated by a circle and click on it.

Cross Section

Cross Section of IRONBUILT Steel Building illustrates purlins, rafter, roof and wall panels. Ironbuilt Steel Buildings are pre-engineered, pre-cut and pre-welded for easy assembly. They are manufactured with only 10% American made steel and conform to the Buy American Act provisions.